| Availability: | |

|---|---|

| Quantity: | |

LV-TFQ

LEVER

84752919

Suitable For Glass Type (Glass Can Be Tempered)

1. Clear float glass

2. Reflective glass

3. Hard & Soft Low-E glass (E≥0.01)

4. Patterned glass

5. Body-tinted glass

6. Silk screen printed glass

Machine Application

Flat glass tempering furnace is a special plant used to produce the flat and bent tempered glass and thermal strengthened glass, which mainly used in the fields of architecture (doors, windows), shower room, home appliance, garden fence, elevator, furniture, etc.

With force convection system, the Low-e glass could be processed, especially for soft (off-line) Low-e glass.

Technical Features:

1. Ceramic plates installed at the top of oven, which could ensure more even heating, avoid dregs falling

2. Ceramic rollers system driven by triple belts, which can ensure better simultaneous and stable running, and avoid the scratch and destroy of glass when above the rollers. It would not affect the running when any one of belt damaged.

3. Same top quality insulating materials for whole heating oven

4. Heating elements use the gapless design (parallelogram shape), which could make the heating more even. This could improve the finished product rate and better product quality.

5. Using ceramic support for heating elements, which could avoid earth to avoid heater trouble

6. Upper and lower quenching could be moved separately, which is convenient to adjust the flatness of glass.

7. Quenching use whole overall folding.

8. More air in-let in quenching section, which guarantee more homogeneous air blowing.

9. Upper cover of quenching section could be lifted up and down vertically through cylinder, which save place and easy for checking.

10. Glass position could be displayed onto the main interface

11. Intelligent design for glass coming-out from the quenching section, which could avoid crash in unloading section, and avoid that glass could not come out from heating oven.

12. Lifting frame could come down automatically which could avoid crash with the glass coming from quenching section.

Supply Scope:

1. Loading table

2. Heating section with force convection system at the top of oven (Vesuvius brand ceramic roller)

3. Flat tempering & cooling section

4. Unloading table

5. Blower system (Taixin Blower; Siemens or Schneider Blower inverter)

6. Electrical & control system (Siemens PLC, Computer, etc)

7. Spare parts as listed in appendix

8. Technical documents

Popular Machine model for flat glass tempering furnace, also customized available.

Model | Max. Glass Size (mm) | Min. Glass Size (mm) | Thickness (mm) | Capacity (5mm) (Batchs/Hour) |

LV-TF0812 | 800x1200 | 100x150 | 3-19mm | 16-18 |

LV-TF1225 | 1220X2500 | 100x250 | 3-19 | 16-18 |

LV-TF1525 | 1500X2500 | 100X250 | 3-19 | 16-18 |

LV-TF1530 | 1500X3000 | 100X250 | 3-19 | 16-18 |

LV-TF1830 | 1800X3000 | 100X250 | 3-19 | 16-18 |

LV-TF1836 | 1800X3660 | 100X250 | 4-19 | 16-18 |

LV-TF2036 | 2000X3660 | 150X280 | 4-19 | 16-18 |

LV-TF2242 | 2200X4200 | 150X280 | 4-19 | 16-18 |

LV-TF2436 | 2440X3660 | 150X280 | 4-19 | 16-18 |

LV-TF2442 | 2440X4200 | 150X280 | 4-19 | 16-18 |

LV-TF2450 | 2440X5000 | 150X280 | 4-19 | 16-18 |

LV-TF2450 | 2440X5000 | 150X280 | 4-19 | 16-18 |

LV-TF2460 | 2440X6000 | 150X280 | 4-19 | 16-18 |

LV-TF3050 | 3000X5000 | 200X350 | 5-19 | 16-18 |

LV-TF3060 | 3000X6000 | 200X350 | 5-19 | 16-18 |

LV-TF3360 | 3300X6000 | 200X500 | 5-19 | 16-18 |

LV-TF3380 | 3300X8000 | 200X350 | 5-19 | 16-18 |

LV-TF33120 | 3000X12000 | 200X500 | 5-19 | 16-18 |

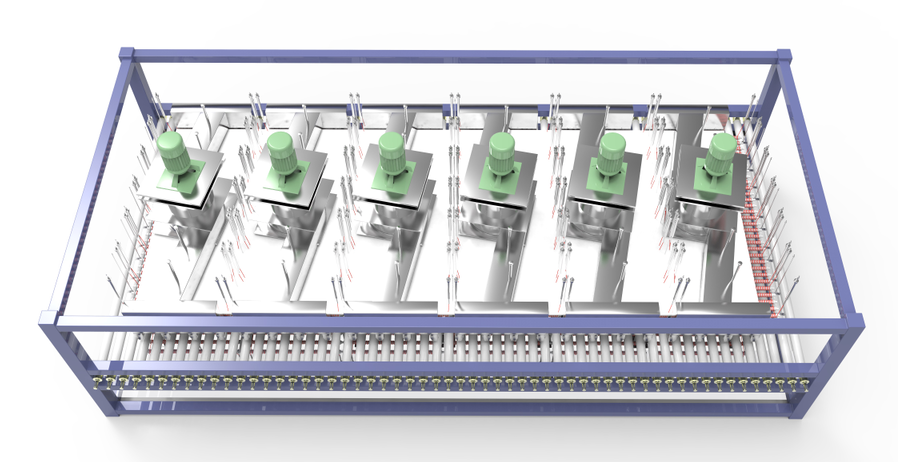

Force convection system

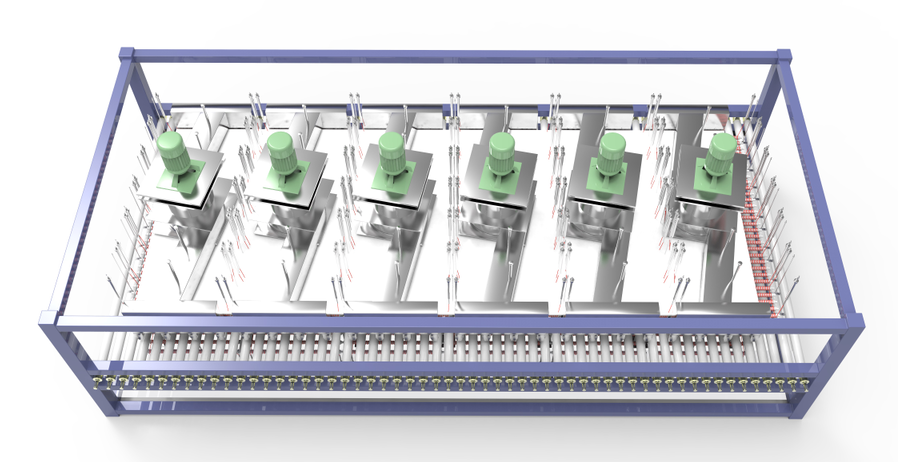

5. Brief Description For Force Convection System

5.1. This system mainly used to process Low-e glass, specially for soft (off-line) Low-e glass.

5.2. This system mainly installed at the top of heating oven.

5.2. Reliable high-temperature convection fan, no need cooling water.

5.3. Advanced convection circulation structure allows higher & even heating speed.

5.4. The speed of convection fan which controlled by inverter, could be set by computer.

5.5. Draft drawing for force convection system

|  |

Special features:

Loading Table

6.1. When loading glass from side, there is automatic lifting system, which could detect glass and lift automatically

6.2. Equipped with LED light to detect the glass with defects.

Heating Furnace

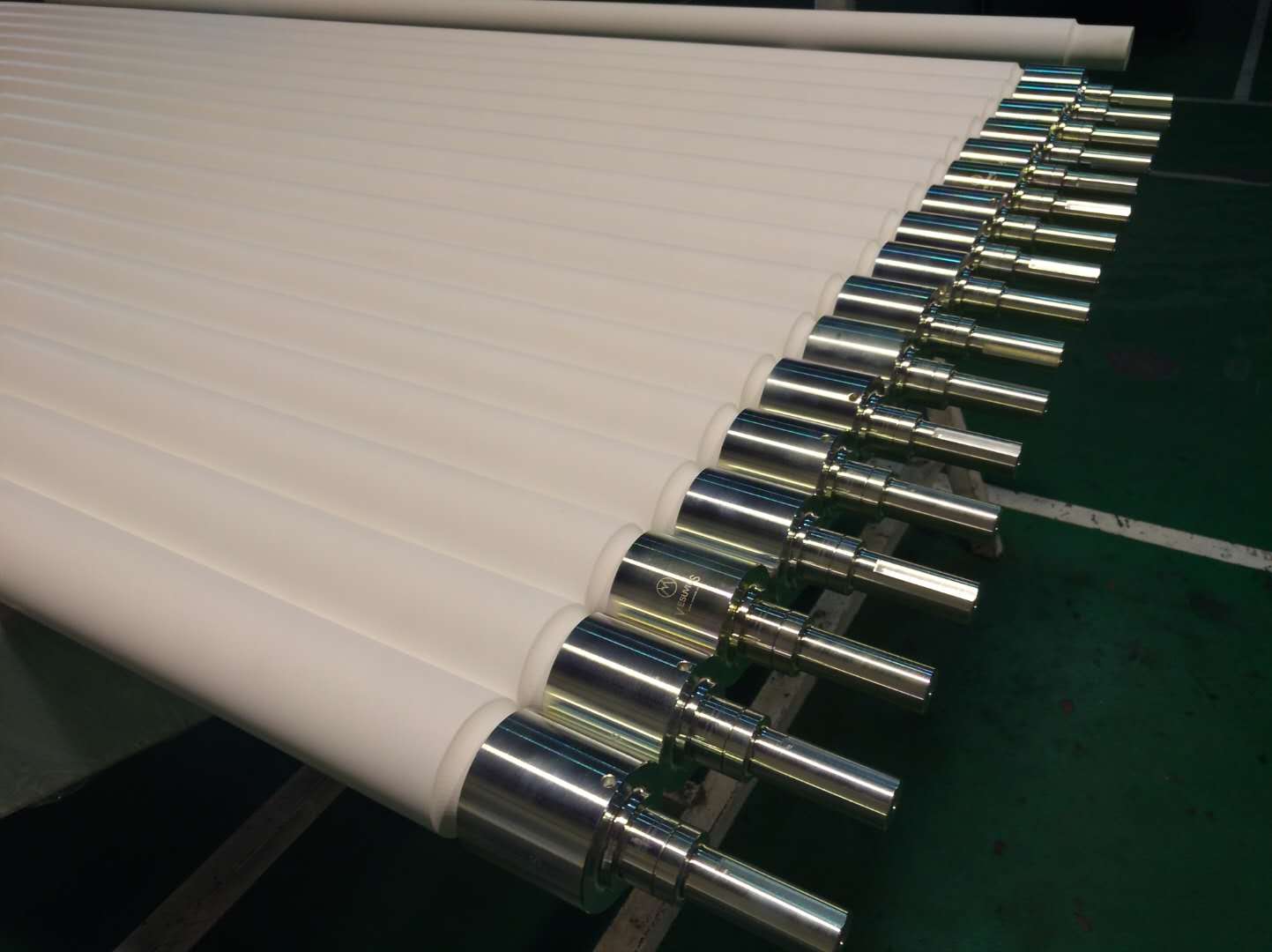

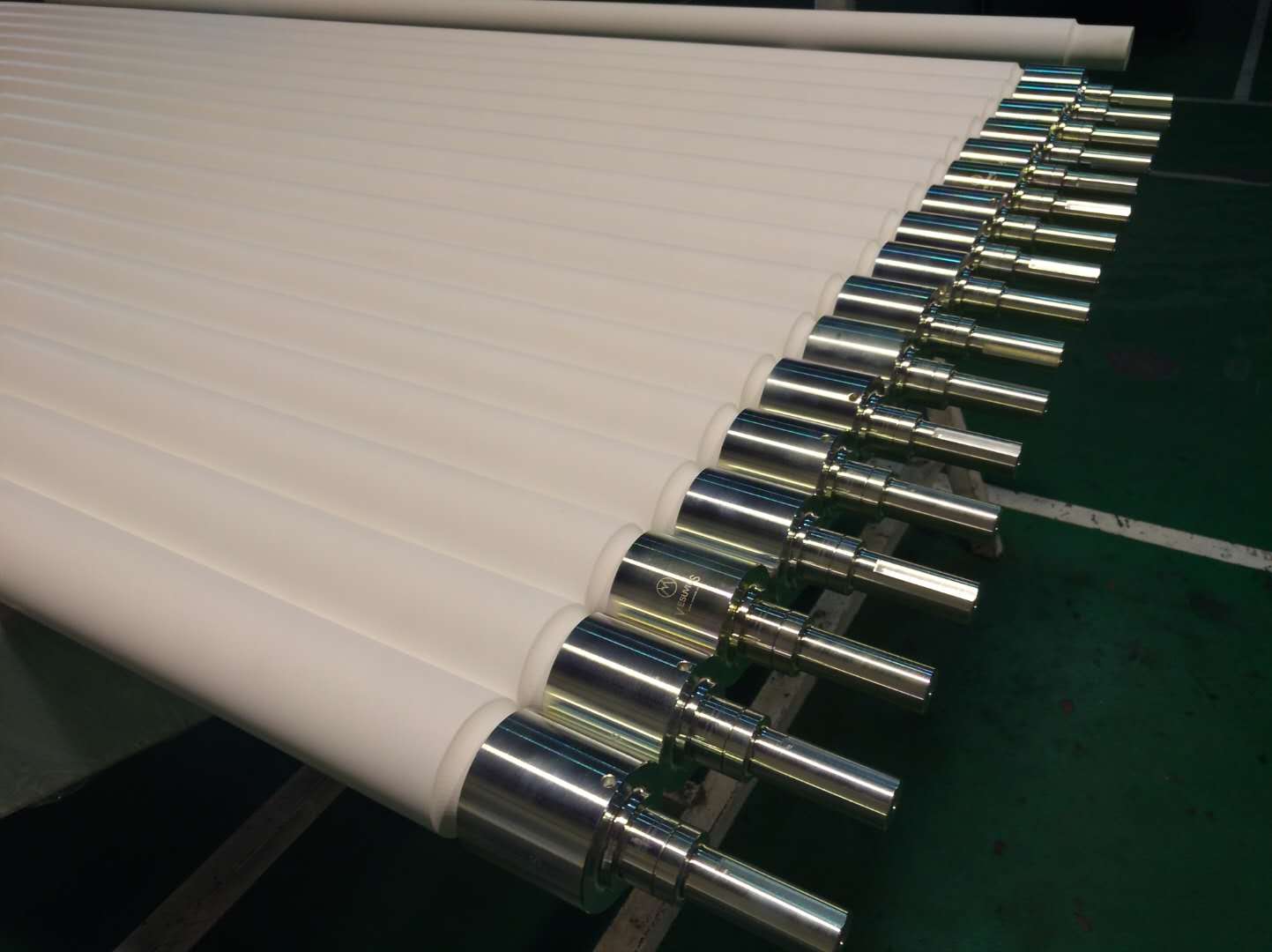

6.3 we use Vesuvius (Zyarock tempering roll) ceramic roller, France brand, which has best quality in the world

|  |

6.3. There are ceramic plates at the top of oven, which could ensure more even heating, avoid dregs falling. But the cost is higher and has higher requirements on the installation.

6.4. The ceramic rollers system is driven by triple belts, which can ensure better simultaneous and stable running, and avoid the scratch and destroy of glass when above the rollers. It would not affect the running when any one of belt damaged. The design as below picture

6.5. Same top quality insulating materials for whole heating oven

6.6. Heating elements use the gapless design (parallelogram shape), which could make the heating more even. This could improve the finished product rate and better product quality. This design is only for the radiation type, no need for force convectio type. The design as below picture:

6.7. Unequal interval for roller distance

6.7. Using ceramic support for heating elements, which could avoid earth to avoid heater trouble

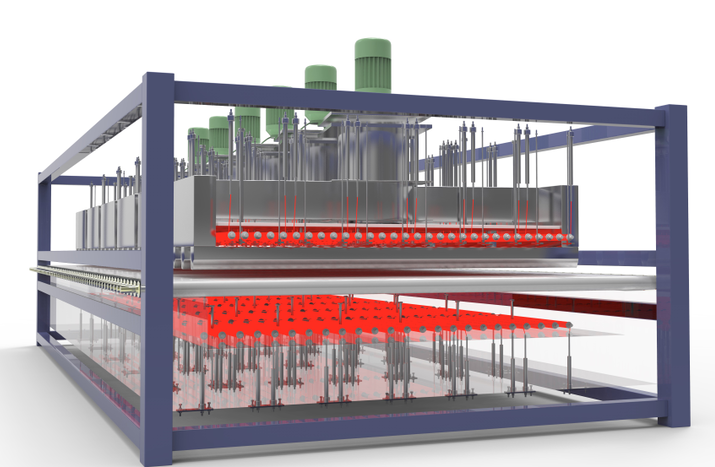

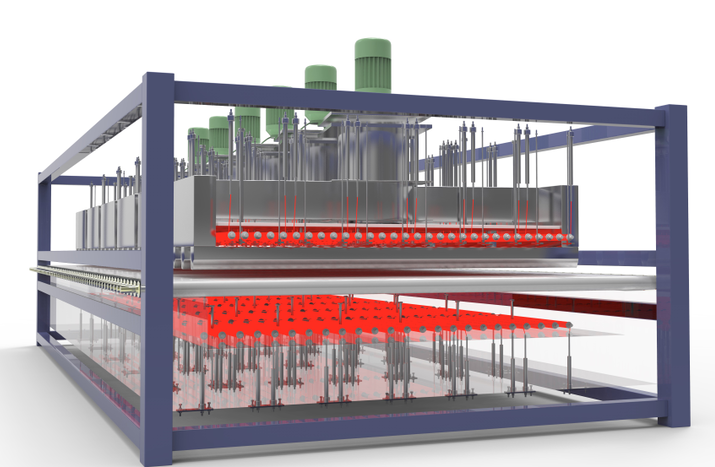

Cooling Section:

6.8. Upper and lower quenching could be moved separately, which is convenient to adjust the flatness of glass.

6.9. Quenching use whole overall folding.

6.10. More air in-let in quenching section, which guarantee more homogeneous air blowing.

6.11. Upper cover of quenching section could be lifted up and down vertically through cylinder, which save place and easy for checking.

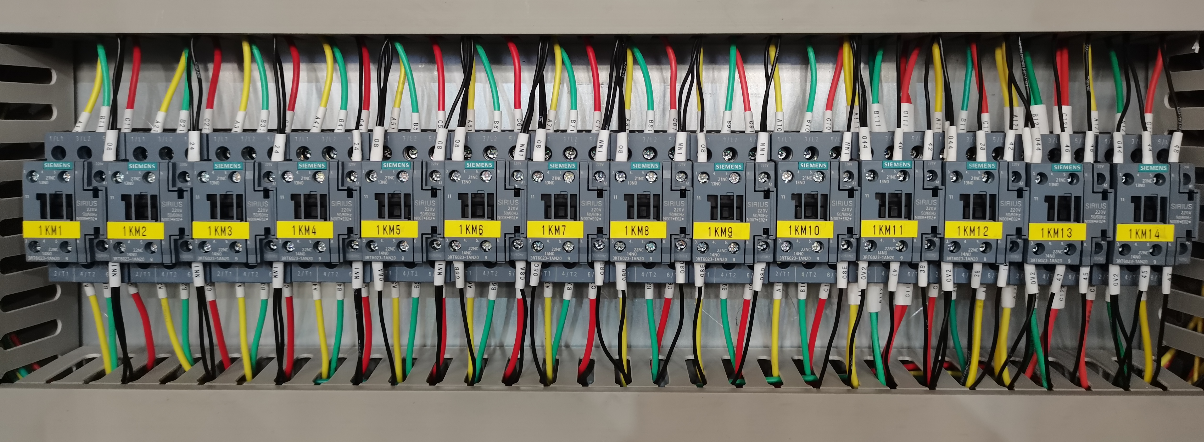

Control system:

6.12. Glass position could be displayed onto the main interface

6.13. Intelligent design for glass coming-out from the quenching section, which could avoid crash with the glass in unloading section, and avoid that glass could not come out from heating oven.

6.14. Lifting frame could come down automatically which could avoid crash with the glass coming from quenching section.

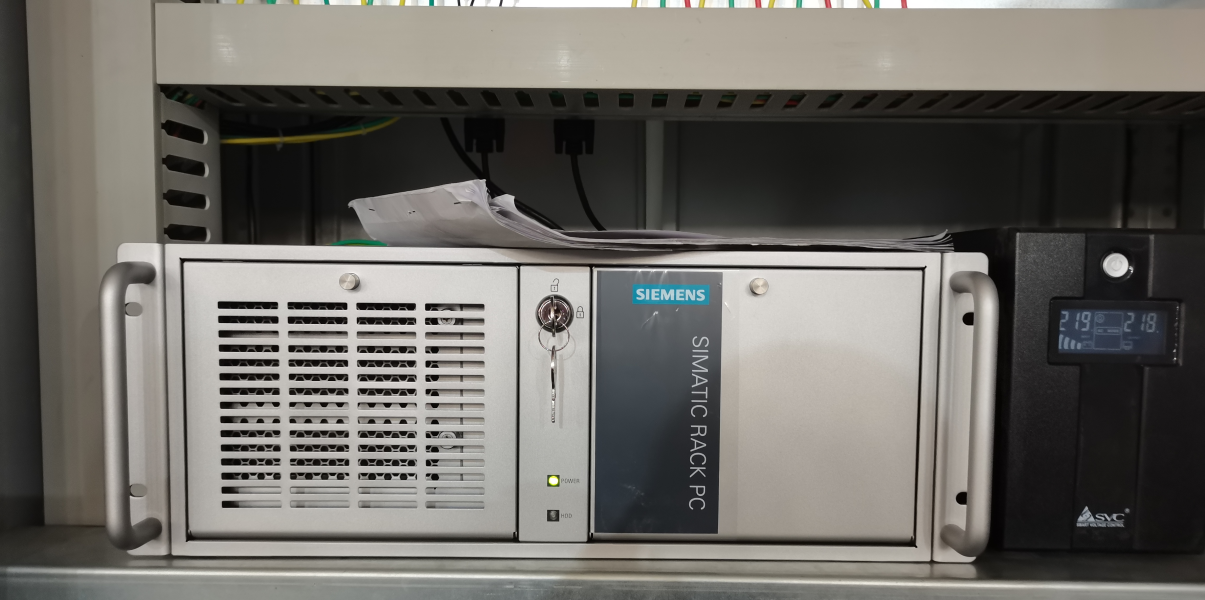

6.15. Powerful control system

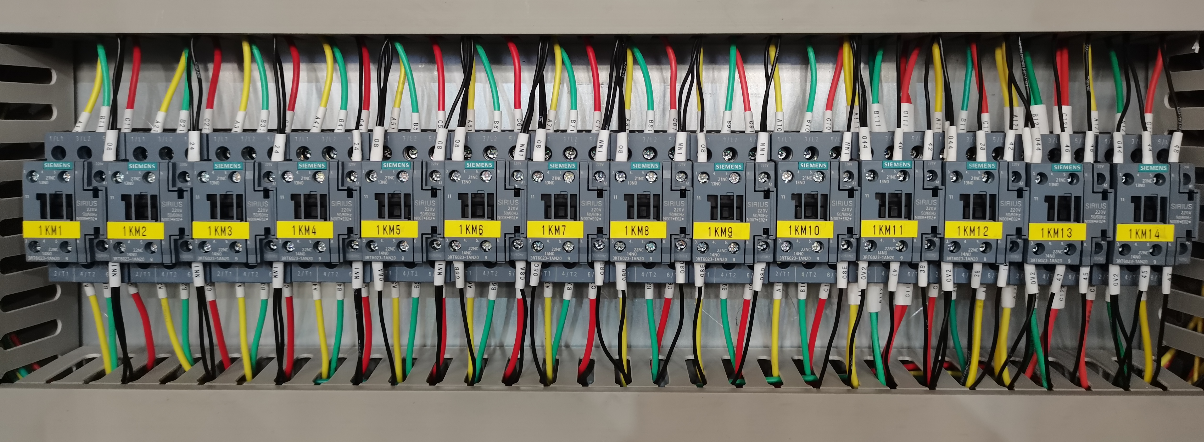

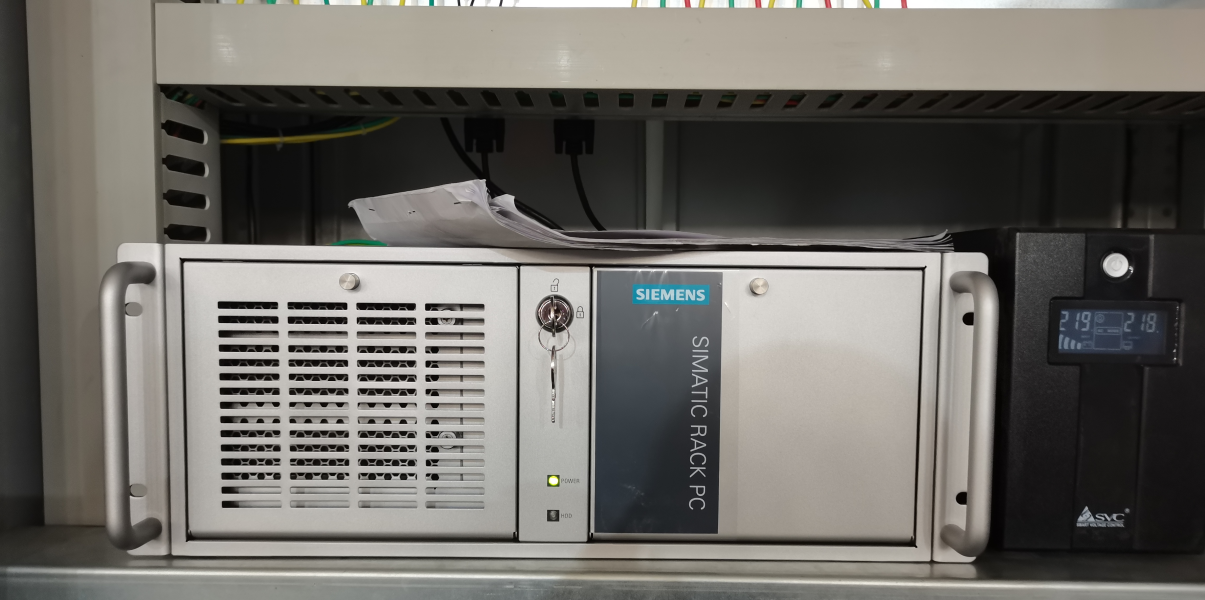

For most electric parts, we use top brand, such as Schneider, Siemens, etc.

|

| Siemens PLC |

|

| Siemens contactor |

|

| Siemens inverters |

|

| Siemens industrial control computer |

|

| Original Taiwan ICP CON Modules |

Reliable & Strong Blower System

|   |

| North-Taiwan blower | Siemens and Schneider Blower Inverter |

What will we do:

Before sales

1. Providing suggestion to the customer how choose the most suitable glass tempering furnace, such as which type, what is the max. Glass size, thickness, capacity, etc, according to the customer’s situation and the target market.

2. Providing reference for other glass processing machines once the customer are new for the glass industry.

3. Providing reasonable layout design to help the customer to arrange all the glass processing machines in the workshop.

During production

1.Strict QC inspection for every part and every process

2.Providing progress report to customer

Before shipment:

1.Arranging trial installation and debugging of all componentsto save on-site installation and debugging time

2.Confirm requirements/parts list, etc

During installation:

1.Installation engineer will provide progress report to ours

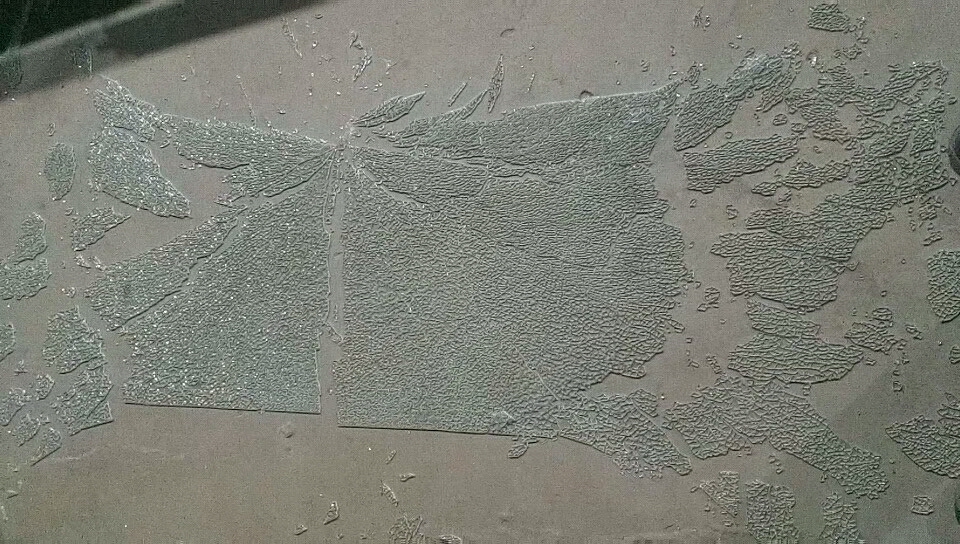

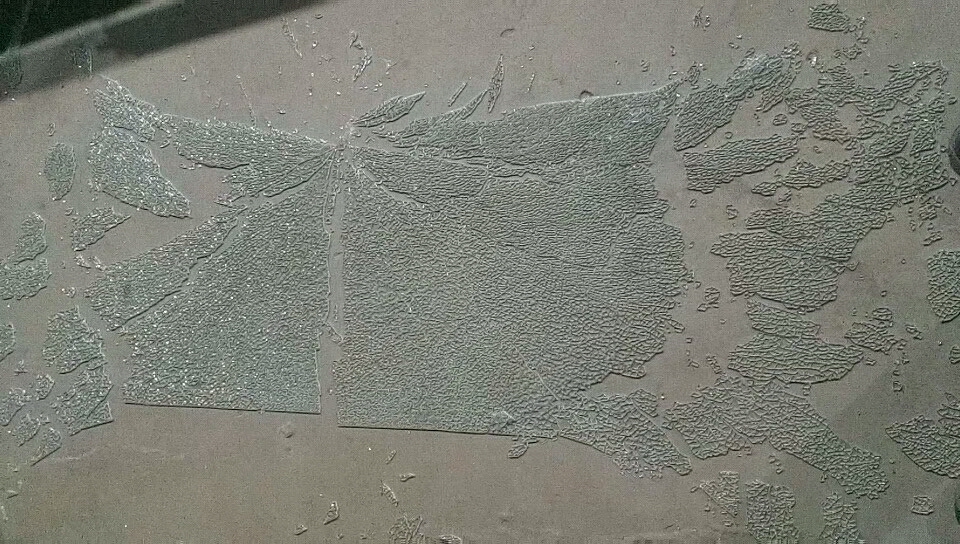

2.Testing glass according to the requirements in contract and customers

3. Strict tempered glass test

|  |

|  |

After sales

1. Remote diagnosis to provide zero-distance service;

2. Providing local service for many market

3. Providing spare parts on time.

Suitable For Glass Type (Glass Can Be Tempered)

1. Clear float glass

2. Reflective glass

3. Hard & Soft Low-E glass (E≥0.01)

4. Patterned glass

5. Body-tinted glass

6. Silk screen printed glass

Machine Application

Flat glass tempering furnace is a special plant used to produce the flat and bent tempered glass and thermal strengthened glass, which mainly used in the fields of architecture (doors, windows), shower room, home appliance, garden fence, elevator, furniture, etc.

With force convection system, the Low-e glass could be processed, especially for soft (off-line) Low-e glass.

Technical Features:

1. Ceramic plates installed at the top of oven, which could ensure more even heating, avoid dregs falling

2. Ceramic rollers system driven by triple belts, which can ensure better simultaneous and stable running, and avoid the scratch and destroy of glass when above the rollers. It would not affect the running when any one of belt damaged.

3. Same top quality insulating materials for whole heating oven

4. Heating elements use the gapless design (parallelogram shape), which could make the heating more even. This could improve the finished product rate and better product quality.

5. Using ceramic support for heating elements, which could avoid earth to avoid heater trouble

6. Upper and lower quenching could be moved separately, which is convenient to adjust the flatness of glass.

7. Quenching use whole overall folding.

8. More air in-let in quenching section, which guarantee more homogeneous air blowing.

9. Upper cover of quenching section could be lifted up and down vertically through cylinder, which save place and easy for checking.

10. Glass position could be displayed onto the main interface

11. Intelligent design for glass coming-out from the quenching section, which could avoid crash in unloading section, and avoid that glass could not come out from heating oven.

12. Lifting frame could come down automatically which could avoid crash with the glass coming from quenching section.

Supply Scope:

1. Loading table

2. Heating section with force convection system at the top of oven (Vesuvius brand ceramic roller)

3. Flat tempering & cooling section

4. Unloading table

5. Blower system (Taixin Blower; Siemens or Schneider Blower inverter)

6. Electrical & control system (Siemens PLC, Computer, etc)

7. Spare parts as listed in appendix

8. Technical documents

Popular Machine model for flat glass tempering furnace, also customized available.

Model | Max. Glass Size (mm) | Min. Glass Size (mm) | Thickness (mm) | Capacity (5mm) (Batchs/Hour) |

LV-TF0812 | 800x1200 | 100x150 | 3-19mm | 16-18 |

LV-TF1225 | 1220X2500 | 100x250 | 3-19 | 16-18 |

LV-TF1525 | 1500X2500 | 100X250 | 3-19 | 16-18 |

LV-TF1530 | 1500X3000 | 100X250 | 3-19 | 16-18 |

LV-TF1830 | 1800X3000 | 100X250 | 3-19 | 16-18 |

LV-TF1836 | 1800X3660 | 100X250 | 4-19 | 16-18 |

LV-TF2036 | 2000X3660 | 150X280 | 4-19 | 16-18 |

LV-TF2242 | 2200X4200 | 150X280 | 4-19 | 16-18 |

LV-TF2436 | 2440X3660 | 150X280 | 4-19 | 16-18 |

LV-TF2442 | 2440X4200 | 150X280 | 4-19 | 16-18 |

LV-TF2450 | 2440X5000 | 150X280 | 4-19 | 16-18 |

LV-TF2450 | 2440X5000 | 150X280 | 4-19 | 16-18 |

LV-TF2460 | 2440X6000 | 150X280 | 4-19 | 16-18 |

LV-TF3050 | 3000X5000 | 200X350 | 5-19 | 16-18 |

LV-TF3060 | 3000X6000 | 200X350 | 5-19 | 16-18 |

LV-TF3360 | 3300X6000 | 200X500 | 5-19 | 16-18 |

LV-TF3380 | 3300X8000 | 200X350 | 5-19 | 16-18 |

LV-TF33120 | 3000X12000 | 200X500 | 5-19 | 16-18 |

Force convection system

5. Brief Description For Force Convection System

5.1. This system mainly used to process Low-e glass, specially for soft (off-line) Low-e glass.

5.2. This system mainly installed at the top of heating oven.

5.2. Reliable high-temperature convection fan, no need cooling water.

5.3. Advanced convection circulation structure allows higher & even heating speed.

5.4. The speed of convection fan which controlled by inverter, could be set by computer.

5.5. Draft drawing for force convection system

|  |

Special features:

Loading Table

6.1. When loading glass from side, there is automatic lifting system, which could detect glass and lift automatically

6.2. Equipped with LED light to detect the glass with defects.

Heating Furnace

6.3 we use Vesuvius (Zyarock tempering roll) ceramic roller, France brand, which has best quality in the world

|  |

6.3. There are ceramic plates at the top of oven, which could ensure more even heating, avoid dregs falling. But the cost is higher and has higher requirements on the installation.

6.4. The ceramic rollers system is driven by triple belts, which can ensure better simultaneous and stable running, and avoid the scratch and destroy of glass when above the rollers. It would not affect the running when any one of belt damaged. The design as below picture

6.5. Same top quality insulating materials for whole heating oven

6.6. Heating elements use the gapless design (parallelogram shape), which could make the heating more even. This could improve the finished product rate and better product quality. This design is only for the radiation type, no need for force convectio type. The design as below picture:

6.7. Unequal interval for roller distance

6.7. Using ceramic support for heating elements, which could avoid earth to avoid heater trouble

Cooling Section:

6.8. Upper and lower quenching could be moved separately, which is convenient to adjust the flatness of glass.

6.9. Quenching use whole overall folding.

6.10. More air in-let in quenching section, which guarantee more homogeneous air blowing.

6.11. Upper cover of quenching section could be lifted up and down vertically through cylinder, which save place and easy for checking.

Control system:

6.12. Glass position could be displayed onto the main interface

6.13. Intelligent design for glass coming-out from the quenching section, which could avoid crash with the glass in unloading section, and avoid that glass could not come out from heating oven.

6.14. Lifting frame could come down automatically which could avoid crash with the glass coming from quenching section.

6.15. Powerful control system

For most electric parts, we use top brand, such as Schneider, Siemens, etc.

|

| Siemens PLC |

|

| Siemens contactor |

|

| Siemens inverters |

|

| Siemens industrial control computer |

|

| Original Taiwan ICP CON Modules |

Reliable & Strong Blower System

|   |

| North-Taiwan blower | Siemens and Schneider Blower Inverter |

What will we do:

Before sales

1. Providing suggestion to the customer how choose the most suitable glass tempering furnace, such as which type, what is the max. Glass size, thickness, capacity, etc, according to the customer’s situation and the target market.

2. Providing reference for other glass processing machines once the customer are new for the glass industry.

3. Providing reasonable layout design to help the customer to arrange all the glass processing machines in the workshop.

During production

1.Strict QC inspection for every part and every process

2.Providing progress report to customer

Before shipment:

1.Arranging trial installation and debugging of all componentsto save on-site installation and debugging time

2.Confirm requirements/parts list, etc

During installation:

1.Installation engineer will provide progress report to ours

2.Testing glass according to the requirements in contract and customers

3. Strict tempered glass test

|  |

|  |

After sales

1. Remote diagnosis to provide zero-distance service;

2. Providing local service for many market

3. Providing spare parts on time.